The Formation of IPMMA

Indian Pharmaceutical Industry A Brief:

With more than 20,000 pharmaceutical companies based in India offers tremendous scope for the machinery manufacturers to exploit the potential by providing necessary machinery by ensuring proper design. ease of user application, simple maintenance and also validation protocol for the new equipment that are essential for the pharmaceutical companies The pharmaceutical market is antiapated to more than double to USD1.3 trillon by 2020, with the E7 countries Brazil, China, India, Indonesia, Mexico, Russia and Turkey accounting around for one fifth of global pharmaceutical sales. India is the fourth largest manufacturer of medicines in the world, although in terms of turnover the contribution of the Indian Pharmaceutical Industry is less than 2% of the global total, it is a clear indication that the pnces of medicines in India are the lowest in the world. The manufacturng facilities in India are being upgraded to the standards of the regulated markets Today, India has the highest number of FDA approved facilities outside USA An entire range of manufacturing facilities is being catered by the Indian pharmaceutical machinery industry including Processing (Tablet / Capsule / Liquids / Injectables / Ointments / Dry Syrups) Packaging (Filling / Sealing / Labeling / Cartoning, etc.) Material Handling, R&D Equipment & Instrumentation, and API / Bulk Drug Plant Machineries, etc.

Indian Pharma Machinery Technology The Hallmark Of Trust:

The growth in advancement and up-gradation of technology in machinery has been faster in India. With almost low technology offerings in the initial stage, the Indian machinery today is considered as one that can offer value added engineering with integration of new technologies. Various international companies found it cost effective to work with Indian partners in the form collaborative ventures. The number of joint ventures between foreign and Indian machinery manufacturers is a testimony to the fact that the Indian machinery industry understands the stringent need of pharmaceutical industry and that it can produce international quality at affordable prices. An incresing number of foreign pharmaceutical-machine manufacturers also have recognized India’s achievements and evolution in the industry. Indian machines are manufactured and used in accordance with international standards and do not hazard the inspection and approval of their facility. This is one of the many reasons that India has the most FDA – approved facilities in the world. It is significant to note that India and China are making machinery which are 10-20 times less expensivse than that of those made in the US and Europe. But German made machines are unbeatable and it is difficult for Indian manufacturers to produce machine that match German quality, and prices are undoubtedly more than that of Indian machinery. In future, it will not be surprising to find managers of pharmaceutical companies waging an all-out war in the market to gain competitive leverage, with little or no time to efficiently plan and design their manufacturing processes, which would possibly slash their production costs and increase their bottom line This is a scenario, wherein the Indian machinery will come handy.Like information technology, the Indian machinery industry is all set to make in-roads in the various markets of the world lead a manufacturing revolution. Indian pharmaceutical-machine makers and their Western counterparts increasingly are exploring collaborations and partnerships with each other to innovate or share new technology. Together, they are targeting more price conscious developing countries. In India there are around 800 pharmaceutical machine manufacturing and allied utility service units in the small and medium sector.Through only few companies have made a mark in the area of branded market, a majority of these units undertake job works and supply of custom made machineries taking the location advantage of buyers. With more than 245; IPMMA is surging ahead as the strongest growth catalyst for the Indian pharma machinery industry, which will be a strong backbone to maintain the flagship growth for the Indian pharmaceutical industry. India is today recognised as one of the leading global players in pharma machinery segment.

Foundation

Indian Pharma Machinery Manufacturers’ Association (IPMMA) was founded on 23rd December, 2001 at New Delhi and was registered as a trade association to represent specifically the Indian pharmaceutical machinery manufacturers. The estimated business revenue from this sector which includes processing, packaging, utility equipments and other ancillary products is around Rs.1500 crores out which Rs.200 crores account for exports.

Aims & Objectives

- To work towards the benefit of all the manufacturers of pharmaceutical machinery.

- To particularly give encouragement and recognition to small scale machinery manufacturers.

- To get recognized by National and International associations related to Pharmaceutical industry.

- To get recognized at the Central government offices situated in New Delhi.

- To ensure maintenance of fair business practices in the pharmaceutical industry.

- To encourage unity and provide mutual help within the members.

- To organize meetings / seminars / conferences / exhibitions / trade fairs as required by the members.

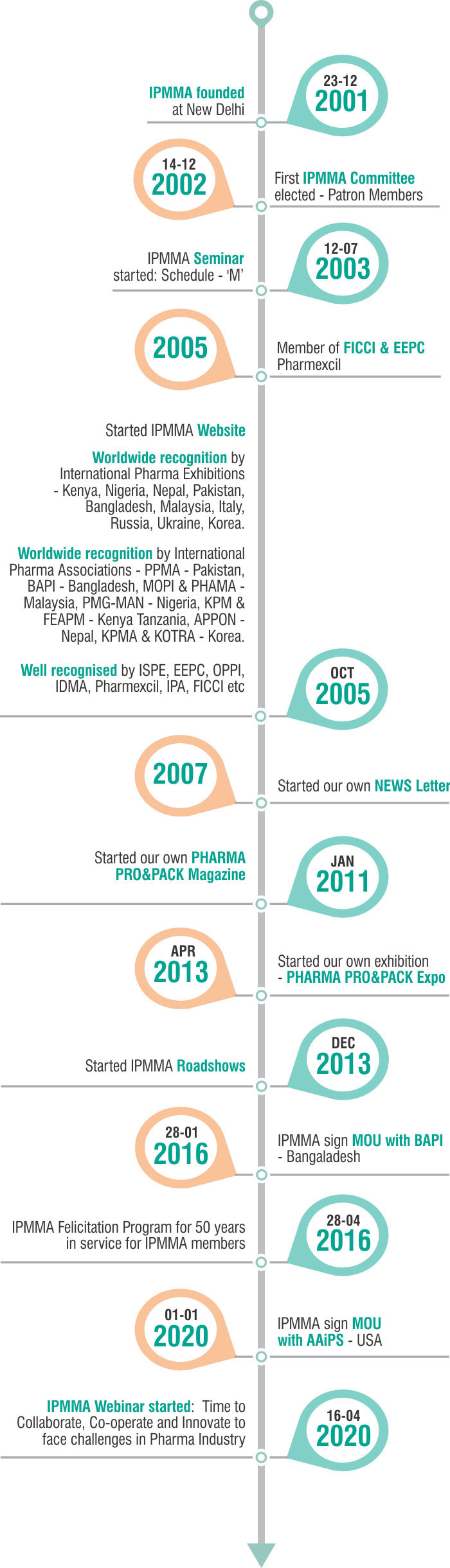

IPMMA Milestone

Role

IPMMA is always committed towards achieving common goals whereby the benefit will go to all the association members. As mentioned earlier Indian pharmaceutical machinery manufacturers have been one of the key contributors in the growth story of the Indian pharmaceutical and drug industry and therefore the association will put all efforts to understand the need for up-gradation of the manufacturing, designing, marketing and banking skills that are required by the industry and try to render help to small members to help them grow corresponding with the growth of the pharmaceutical industry. However these ideas can take concrete shape only in the next few years after the association grows in size to handle such major responsibilities.

The association is already putting efforts to co-ordinate with several agencies, component suppliers etc. to provide necessary knowledge that could be imparted to the members under a single roof program that would help both the supplier as well the industry in order to save time and money for all the parties concerned.

Today IPMMA has already enrolled 300+ members and the association has been recognized by several government, semi-government and trade councils. It is a great pride for the association that these members already export their products to 80 different countries spread across five continents and therefore the association would put efforts to help other non-exporting members to find business inroads into those foreign countries.