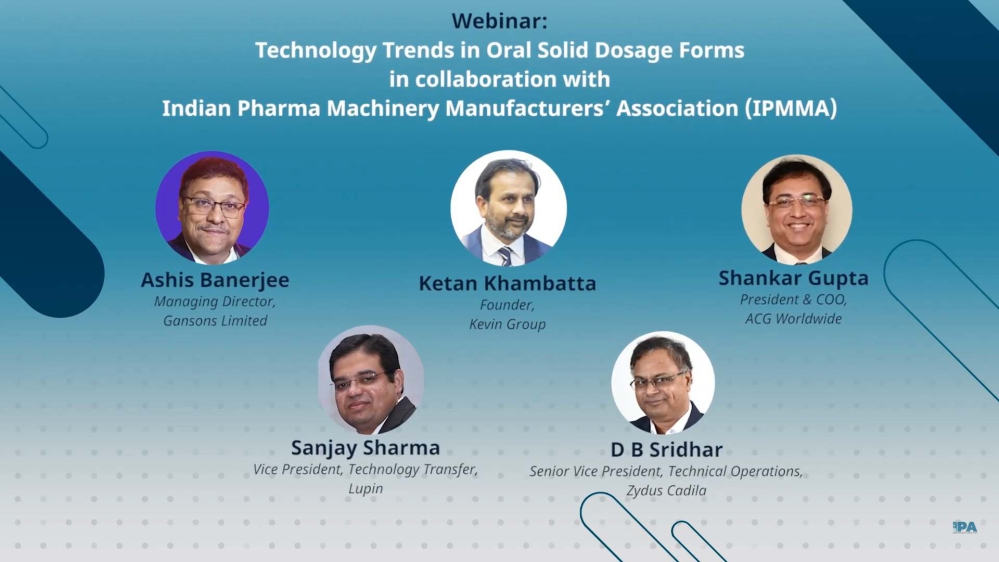

On 7th October 2021, Indian Pharmaceutical Alliance (IPA) in collaboration with Indian Pharma Machinery Manufacturers’ Association (IPMMA) conducted a webinar on ‘Technology Trends in Oral Solid Dosage Forms’ which received a healthy response of 150+ participants from industry and academia.

The webinar was graced by a panel of industry experts Ashis Banerjee, MD – Gansons Limited, Ketan Khambatta, founder- Kevin Group, Shankar Gupta, President & COO – ACG Worldwide, Sanjay Sharma, VP Technology Transfer – Lupin and DB Sridhar, Senior VP Technical Operations – Zydus Cadila.

Sudarshan Jain, Secretary General – IPA kickstarted the webinar on a congratulatory yet motivating note for progress of India pharma industry from global perspective. Mahendra Mehta then presented an overview of the solid dosage form technology and how it has evolved in the last decade complying with regulatory norms yet innovating through-out. Shirish Belapure, Senior Technical Consultant, IPA on a positive note emphasized the importance of Indian Pharma machine manufacturing industry as a keystone in building Indian Pharma industry as a Pharmacy of the world.

Kaushik Desai, Advisor, IPMMA and the moderator of the session while welcoming all the panellists started off with highly interactive session of Q&A focusing on the trends in solid dosage forms technology. The experts provided an excellent insight with practical examples.

Key Takeaways

Ashis Banerjee, MD – Gansons Limited

The content uniformity for a potent drug in low dosage form is more critical. The stability of the tablet dosage form and productivity warrant a very deep and profound thinking both from the angle of formulating the tablet as well as the technologies involved in production. We will in the future see a transition of solid dosage form with a totally new innovative technology. The success of commissioning and smooth operation of machine calls for very effective FAT and SAT with well-defined

Ketan Khambatta, founder- Kevin Group

With evolution of new technologies, continuous manufacturing is taking centre stage slowly. However, steadily in the next few years, the industry is going to change forever with advent of digitisation and automation. 70 percent of the molecules that are being developed today are molecules in the solid dosage form and out of these quite a few are highly potent requiring specialized equipment and knowledge to produce this on both the sides the manufacturer as well as the equipment supplier.

Shankar Gupta, President & COO – ACG Worldwide

In terms of compression machine productivity, the content uniformity and weight variation are very important. MUPS application and bi-layer applications going forward will be of more prominence and traction into the pharmaceutical industry.

Today’s pharma industry is already moving towards digitization moving to data to dashboard based metric systems providing real time data and the production KPIs on a mobile application. The maintenance engineer with real-time feedback could avert a major breakdown, increase up-time and in turn increase the overall efficiency.

Sanjay Sharma, VP Technology Transfer – Lupin Limited

Going forward since most of the product development are likely to become more complex, there would be more patent challenges and the regulatory expectations which are at its peak right now. There has been a lot of initiatives globally in terms of digital transformation, automation, data analytics, creating capabilities for platform technology and also as we all know continuous manufacturing is becoming the new buzz word. The development scientists play a major role insuccessful design of a tablet dosage form.

DB Sridhar, Senior VP Technical Operations – Zydus Cadila

The standardizing of parameters will help the formulations and equipment operations to be more precise. Documents like URS and other qualifications must be given equal importance for having trouble free operations. The operation and machine manufacturer should work together in selection of right kind of machine and the associated systems for better compliance to quality norms. The skilling and reskilling of professionals will be key to implementation of new technology.

The webinar concluded with satisfying participants on several queries. The feedback to this webinar was very encouraging. IPMMA and IPA has plans to conduct such collaborative technical webinars on a continuous basis.

Leave a Reply

You must be logged in to post a comment.